As an industry benchmark, SHENGHONG has been promoting green transformation in order to better serve our customers, and fulfill the vision of developing a greener and more sustainable future.

In addition to the current physical regeneration method, SHENGHONG has been thinking about how to create more innovation in green products. CCUS provides us with new ideas to turn CO2 emitted in factories into environmental products, and we are on the way to realizing it. In the future, the textiles we wear and use at home may all come from industrial carbon emissions.

SHENGHONG started developing regenerated fibers in 2015. After years of research, SHENGHONG has mastered the world's leading technology for producing regenerated fibers and developed a set of direct spinning technology for regenerated bottle flakes with quality standards identical to those of the virgin.

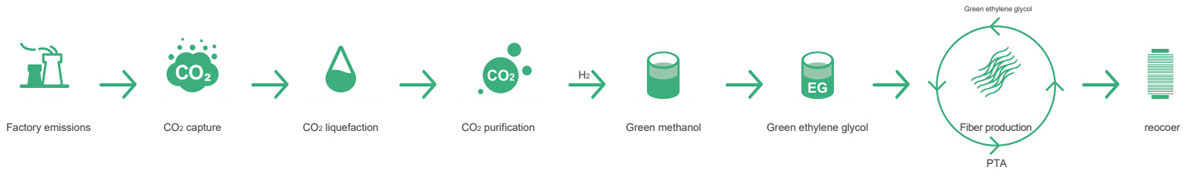

In September 2021, SHENGHONG launched the 150,000-ton CO2 capture and comprehensive utilization project and took the lead in initiating the 'carbon dioxide capture&utilization - green methanol - green ethylene glycol' industrial chain to achieve the goal of carbon reduction.

SHENGHONG carbon capture technology synthesizes green methanol from CO2 and H2 as raw materials under certain conditions, absorbing 150,000 tons of CO2 and converting 100,000 tons of methanol annually. Just like afforestation, this device simulates photosynthesis to absorb CO2 with a recovery and conversion rate of nearly 100%, indirectly reducing CO2 emissions by 550,000 tons per year, equivalent to planting 37,000 hectares of forest.

SHENGHONG carbon capture technology collects and converts the CO2 emitted by factories to produce green ethylene glycol and our factories polymerize green ethylene glycol and PTA into carbon capture fibers. (brand name: REOCOER)

REOCOER carbon capture fibers are fully traceable and suitable for all knitted and woven fabrics. All specifications of POY, DTY, and FDY can be produced.

Reocoer reduces carbon emissions by 28.4% compared to virgin yarns.(Data from SGS).

SHENGHONG aims for long-term sustainable development and is committed to bringing about a lasting change in carbon emissions. REOCOER builds a green industrial chain of 'CO2 chemical fiber new materials', creating a new path of 'turning carbon into treasure', and driving the industrial chain with a low-carbon economy.

Our core business and technology have been making contributions to the future. Through the green ethylene glycol project, REOCOER converts the carbon emissions that would otherwise flow into the atmosphere into new sustainable chemical fiber materials. All processes are completed internally, using CO2 to manufacture fibers. Each ton of yarn can capture 320KG of CO2, effectively promoting a carbon circular economy, reducing carbon emissions, and providing sustainable products with less environmental impact to consumers.

In addition to our technology, good governance is the foundation of our operations. We believe that strong governance promotes a culture of integrity at all levels of the company by increasing accountability. Transparency, supervision, compliance, and ethical practices help us better understand social issues related to our business and daily operations, and also enable us to have a clearer understanding of customer demands in order to offer our customers better quality products and services.

The planned annual production capacity for the first phase is 30,000 tons, which is equivalent to collecting nearly 10,000 tons of CO2 and equal to the amount of CO2 absorbed by one million trees in one year, creating 15,000 acres of forest for the Earth.

In the second phase, we will increase our production capacity to 200,000 tons per year to meet the demands of our customers. In the future, we will continue to increase production capacity to reduce more CO2 emissions.